Chitosan for Wine Clarifying

The use of “animal-free” chitosan agents in winemaking has gained popularity during the last decade. Chitosan is a natural (charged) polysaccharide produced by deacetylation of chitin [poly-β-(1 → 4)-N-acetyl-D-glucosamine] under alkaline conditions. There are numerous chitosan variations due to differences in deacetylation, molecular weight, and formulation preparation (granulometry in particular) that result in chitosan and chitin-glucan molecules with a variety of properties, characteristics and activities.

After cellulose, chitin is the most prevalent polysaccharide in nature, and it is the principal component of fungus and plant cell walls, insect skeletons, and crustacean shells. Despite the fact that chitosan is insoluble in wine (or water), only fungal chitosan and chitin-glucan (from Aspergillus niger) are allowed in winemaking to avoid any allergic reactions induced by impurities from processing crustacean material. Chitosan and chitin-glucan are winemaking processing aids that have been approved for use in winemaking, (OIV and FSANZ) and have been certified for use in organic winemaking (ACO).

|

Type of use |

Winemaking Target |

|

Reduction of undesirable microorganisms |

Yeast: Brettanomyces |

|

Settling, clarification & prevention of protein haze |

Protein removal |

|

Antioxidant activity |

Reduction in browning |

|

Reduction of heavy metal content |

Cu, Fe, Pb, Cd |

|

Reduction of contaminants |

Ochratoxin A |

Table 1. Applications of chitosan and chitin-glucan in winemaking (summarised from Marín et al., 2020).

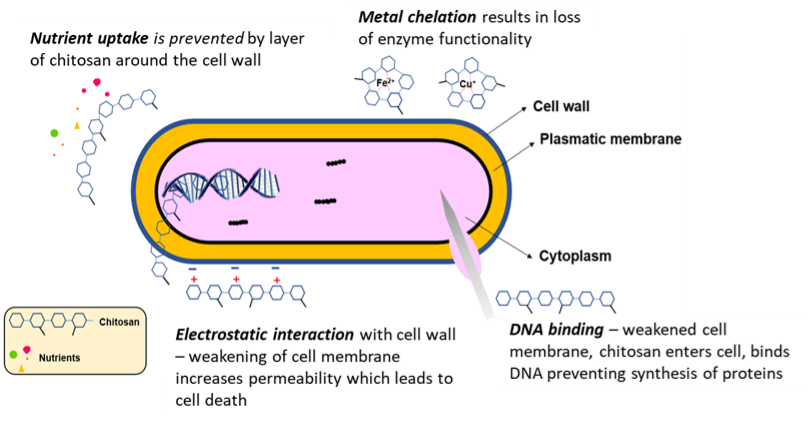

Microbial Growth Control & Elimination

Chitosan has attracted great attention in the food and wine sector, due to its antibacterial properties (Figure 1). While still unclear, hypotheses of chitosan antimicrobial mechanisms include a change in cell permeability caused by the electrostatic interaction between the positively charged molecules of chitosan and the negatively charged molecules of microbe cell membranes (causing a leak of the cytoplasm constituents). Other mechanisms include the interaction of hydrolysis products with microbial DNA (which causes the inhibition of the mRNA) and protein synthesis, in addition to the chelation of metals, spore elements, and essential nutrients (No et al., 2007; Marín et al., 2020). This antimicrobial activity makes chitosan a very versatile product for food technologists. For example, it can be used for extending the shelf life of bread or the storability of perishable commodities (oxidation barrier effect), including fruits and vegetables when applied as an edible coating, followed by cold storage (No et al., 2007).

Figure 1. Proposed antimicrobial activity mechanisms of chitosan and chitin-glucan (adapted from Marín et al., 2020).

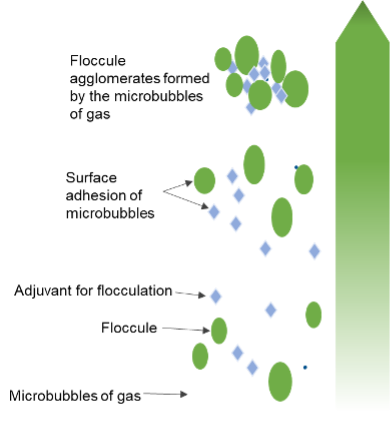

Chitosan As Flotation Adjuvant

Flotation consists of injecting gas bubbles (e.g., nitrogen or air) into the juice prior to the alcoholic fermentation in order to separate grape solids from the juice. More specifically, the suspended particles stick to the gas microbubbles where they are floated off and separated out. The flotation process requires the application of adjuvants that form floccules through the aggregation of the juice particles and the pectins. The addition of enzymes is also required to break down the pectin bonds, thus helping the particles to float upwards (Figure 3). While traditional clarification gives a juice that requires from 24 to 48 hours to settle after the addition of fining agents, flotation may take only a few hours (time varies based on winemaking decisions and volumes to treat) to give a juice of around 100 NTU. The juice is then ready to be yeast-inoculated (assuming a post-floating temperature of 15-16°C). Among the other benefits, the juice that needs to be treated does not need to be chilled prior to flotation. This drastically decreases the costs associated with energy consumption.

Conclusion

Fungal origin chitosan and chitin-glucan products are an excellent biological option for winemakers to inhibit detrimental microbial developments such as Brettanomyces spp and spoilage indigenous bacteria, assist with flotation, control oxidation, and chelation of heavy metals. However, it is recommended for winemakers looking to take full advantage of these products to undertake bench trial to determine the optimum product concentration required to achieve the best result for their wine.

Get Free Sample

Email : sales@be-bettertech.com

Telephone : 008613522370429

Skype: Pennyfengnew

Address : F2 BLDG 16 VPark, Yizhuang ED-Zone, Daxing DIST, Beijing of China.

We guranctee 24-hour response.

Our Advantages

10 Years + Experience

Powerful R&D

Expert & Doctor Advise

Factory Price Only

Customized Viscosities etc...

High& Middle & Low MW

Sea Source & Fungal Source

Fast Response

7-Day-Delivery

Sample Test